Realizing that maintenance and repair costs of plant floors include lost production time, inefficiencies, worker comfort and safety, our customer was concerned about protecting the expensive concrete floors in their brand new facility.

Committed to a failure-free environment, an aircraft manufacturer challenged Hamilton to a create heavy duty caster with a low contact pressure.

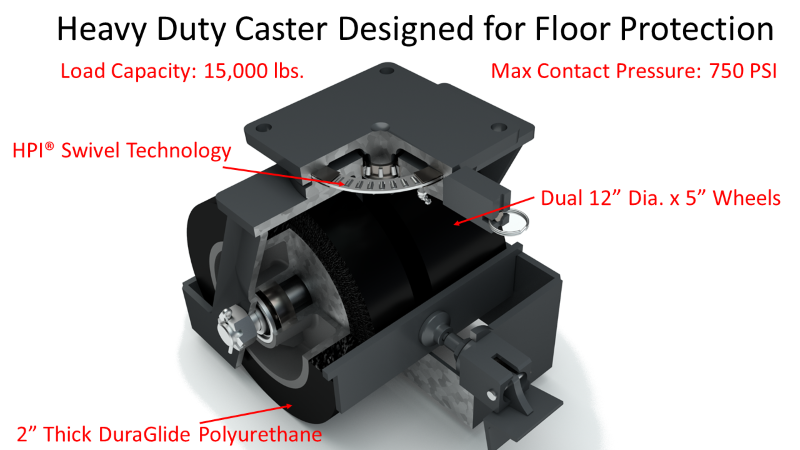

The company required 128 heavy duty casters each rated at 15,000 lbs. and designed to apply a maximum contact pressure of 750 psi per caster to the concrete floors. No small task.

Working with our customer and a key supplier, a four-person team at Hamilton buckled down. Using computer modelling, the team zeroed in on a polyurethane wheel design that achieved the desired results.

Success!

mouseover to zoom

After hours of computer simulation, the prototype exceeded the customer requirements resulting in a wheel with two-inch thick tread of Hamilton's new DuraGlide polyurethane material that delivered 698 psi per caster, well below the customer’s psi requirement.

Once the wheel spec was finalized, Hamilton machined and fabricated the dual wheeled caster with a toe guard and a dual heavy duty brake.

The client appreciated Hamilton’s efforts. “You were the only supplier to dig in your heels and come up with a solution. Hamilton was committed to meeting our challenge. The magic worked and the casters are on the stands. Thank you again for all of the technical support! These are cool!!!