Custom All Stainless Steel Caster Rolls in Line

Monday, Jul 29, 2013

What began as a simple wheel order spawned into a new Hamilton innovation when our engineering manager, Jeff Spektor, realized a fresh design could save a major aerospace supplier big bucks – and headaches.

“When I saw what the customer needed, I knew a standard wheel wouldn’t work,” he said. “So we came up with a unique design that exceeded the customer’s expectations – an all-stainless steel caster with inline wheels.”

Building a Caster to Biohazard Standards

Several factors made this job unique, especially the federal regulations for the room where our casters are used. Everything inside the clean-room environment, including our casters, must adhere to strict standards so nothing damages the sensitive (and top-secret) equipment being tested.

That’s why we chose an ultra durable, high-grade stainless steel (316L) that has superior corrosion and pitting resistance, and performs extremely well under continuous use. 316L contains less carbon than industry-standard 303 or 304 stainless steel and we avoid contamination during the welding process.

Inline Wheels Stay on Track

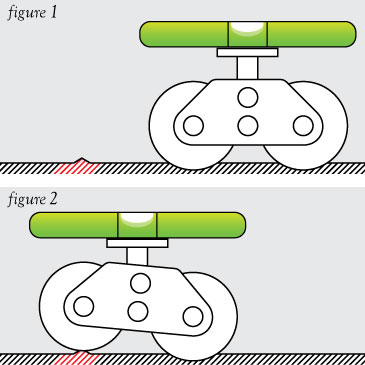

Unlike a dual-wheel caster that features wheels side by side, this caster, rated up to 15,500 lbs., runs with back-to-back wheels that support each other. It rolls on rails that presented a special set of challenges that we overcame.

For example, when the first wheel goes over a small hump on the tracks, the back wheel stays on the ground to keep the load completely flat. See the illustration below to better understand how they work:

Learn More About Hamilton’s Custom Engineered Capabilities

Whether you need a custom caster for a unique application, or something more standard, Hamilton can solve any material-handling problem. Let’s talk. Call or email Jim Lippert, vice president of sales, 1-800-733-7655.