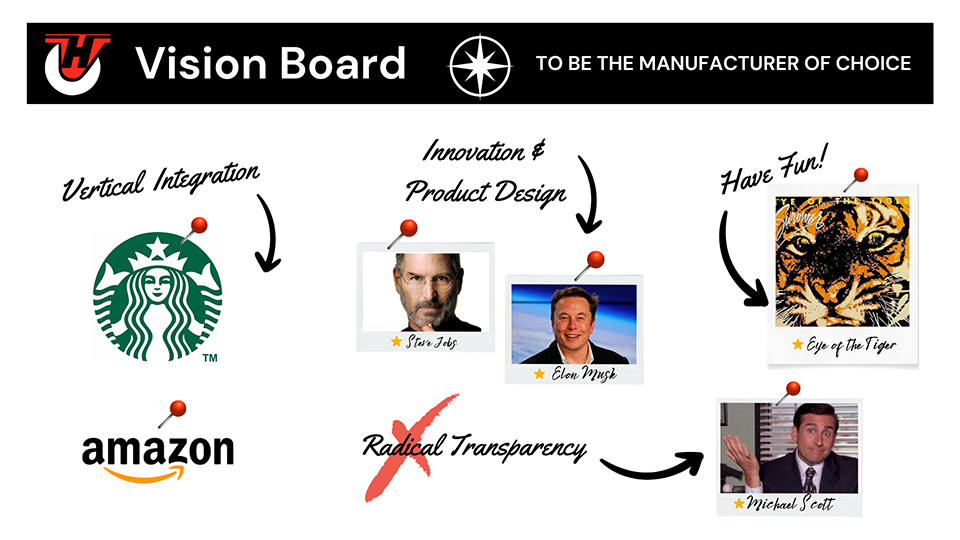

If we had to create a Vision Board for Hamilton’s year ahead, it might include:

- 1. Signed headshots of Elon Musk and Steve Jobs (symbolizes our commitment to innovation and product design)

- 2. Photo of “The Office’s Michael Scott (okay, so maybe he goes too far on radical transparency, but you get the idea)

- 3. Starbucks & Amazon (great examples of vertically integrated supply chains)

- 4. A photo of the band Survivor (duh, Eye of the Tiger)

At Hamilton, we want to be the manufacturer of choice for heavy-duty industrial casters, wheels and carts, and custom-engineered mobility systems. To get us there, we’ve got a host of strategic initiatives planned for 2024 that we want to share with you.

Supply chain alchemy and lead time goldEvery year we review our Mission and Vision to see if we’re on track to achieve our “Perfect North”. To help us identify gaps and optimize our strategy, we employ various tools such as SWOTs, PESTEL, and Porter’s Five Forces. It’s a great opportunity to check in with the head and heart of Hamilton. As we’ve discussed in the past, improving lead times has been a huge focus for us, and we’ve worked diligently to achieve our current industry-leading lead times by employing strategies such as dual vendor sourcing of our raw material.

In 2024, we’re taking our commitment to supply chain resilience to the next level, having built considerable groundwork on a formalized supply chain structure, complete with scorecards and initiatives to strengthen our vendor relationships. From order entry through shipping, we’re also enhancing the flow of information with processes, tools and digital technology to make sure the right people always have the right information at the right time. This not only creates more transparency on order status, but ultimately leads to a better customer experience overall.

Streamlining product designIn 2024, we’re committed to taking a new look at our product design, development and manufacturing. We have a lot of new talent in our engineering department, and we’re tapping their fresh perspectives to rethink and reimagine how we approach our product hardware. There are so many opportunities to simplify the components we use to streamline inventory and assembly (read: less waste without sacrificing quality).

Better vertical integrationTo continue to scale, stay competitive and deliver for our customers, we’re always looking to optimize what we make inhouse versus what we outsource. We’ve identified key investment areas to increase our capabilities and have more control over the production process. This includes evaluating processes such as induction heating, laser cutting and inhouse 5-Axis machining.

“That includes bringing in more expertise around business development and empowering our sales culture. At the end of the day, it’s really about making people’s lives easier, having fun while we do it, and always thrilling the customer.”

New productsWe’ll be rolling out a lot of new products this year that will address the increasing demand in automation. It’s all exciting stuff, and we’d love to tell you more, but we’d have to kill you. Stay tuned to “Revolution” all year long to find out.

Let’s pretend you read none of this story and you want to know the big takeaway. Our President Mark Lippert said it best.

“We want to transform our culture into a growth machine,” he explained. “That includes bringing in more expertise around business development and empowering our sales culture. At the end of the day, it’s really about making people’s lives easier, having fun while we do it, and always thrilling the customer.”