We’re hoping our all-new Hamilton swivel locks have everyone talking about added caster mileage and versatility.

We love a good makeover—especially when it’s as much about progress as it is polish. That’s why we’re pumped to announce our new and improved Hamilton swivel lock. It’s been more than 50 years since our last design, so you could say we were overdue for a pivot (sorry, couldn’t resist).

Why use a swivel lock?

They’re great for turning existing 360-degree swivel casters into stationary/rigid casters on a dime. If your application requires both straight-line tracking (useful for pushing loads long distances) and full-range movement (for maneuvering tight turns), a swivel lock provides the perfect on-the-go versatility.

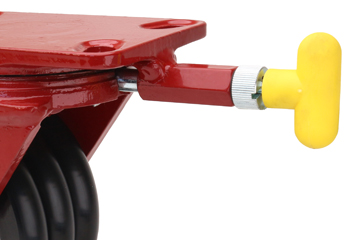

How do swivel locks work? A spring-loaded plunger housed beneath the caster mounting plate positively engages slots milled in the swivel horn base. When retracted, the steel plunger sits in a vertical notch in the housing to hold it clear of the swivel horn. In true Hamilton fashion, we go the extra mile by robotically welding the housing to the rig. The slots for the plunger are also CNC-milled to ensure long-lasting, trouble-free performance.

What’s new and improved about our Hamilton swivel lock?

-

A thick, ergonomically-friendly T-Handle: Provides better leverage—especially for arthritic hands. Safety yellow makes it a easy to locate, too.

-

Quick lock/unlock indication: Easily identify if the caster is locked/unlocked through the handle’s orientation (vertical = locked, horizontal = unlocked…similar to a deadbolt)

It’s a lock: Our new swivel lock design (right) is a welcome update to the version (left).